Complies with WS 507-2016 medical water standard

Multi-layer filtration and sterilization ensure safe, bacteria-free water

Smart automatic start/stop control for stable operation

Internet of Things monitoring and remote management

Compact design, easy installation and maintenance

Suitable for hospitals, clinics, and endoscopy centers

The 120L Medical Pure Water System for Dental and Endoscopy Cleaning is a specialized medical-grade water purification solution designed to deliver consistent, high-quality purified water for hospitals, dental departments, and endoscope reprocessing units. This system combines advanced filtration, sterilization, and intelligent automation technologies to meet the demanding requirements of modern medical cleaning and disinfection environments.

At the core of the system is a single-stage Reverse Osmosis (RO) process, which effectively removes dissolved solids, organic matter, heavy metals, and other impurities from the incoming water. The RO membrane acts as a molecular barrier, ensuring that only pure water molecules pass through while contaminants are flushed away. This process guarantees stable and reliable water quality suitable for medical applications where precision and safety are essential.

To further enhance water purity and prevent microbial contamination, the system employs a multi-sterilization process. This includes a membrane sterilization module, an overflow ultraviolet sterilization unit, an immersion sterilization module, advanced oxidation treatment, and terminal filtration. Each stage plays a crucial role in eliminating bacteria, viruses, and pyrogens, providing an additional layer of protection to ensure that the produced water meets or exceeds WS 507-2016 Regulation for Cleaning and Disinfection Technique of Flexible Endoscope standards. The final output water achieves a conductivity of ≤15 µS/cm (25°C), ensuring exceptionally low ionic contamination.

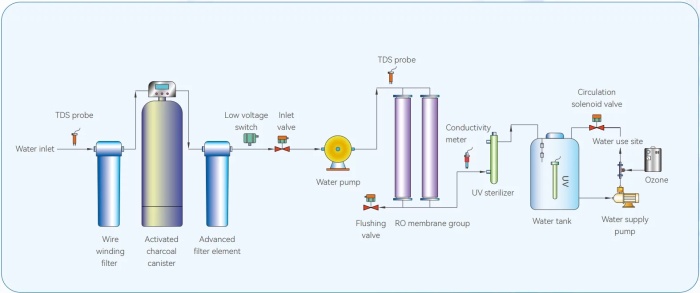

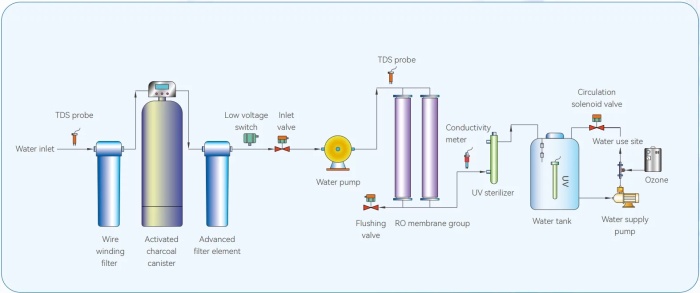

The pre-treatment section of the equipment incorporates a multi-stage filtration setup designed to handle various water qualities from different regions. The first filtration level utilizes a 20-inch thick wire-wound filter to remove large particulates and sediment. The second level features a combination of coconut shell activated carbon and softened resin with an automatic regeneration cycle to eliminate chlorine, odor, and hardness-causing ions. The third level applies a 20-inch precision filter to remove fine impurities before water enters the RO module. This comprehensive pretreatment sequence ensures system longevity and optimal membrane performance even under challenging water conditions.

The system's automation and control features further enhance its performance and user convenience. Equipped with intelligent sensors and microprocessor control, it supports automatic start and stop based on water demand and storage tank levels. The built-in conductivity meter continuously monitors water quality, giving users real-time assurance of system performance. In addition, IoT (Internet of Things) functionality allows for remote monitoring, fault alerts, and performance diagnostics, providing maintenance teams with early warnings and minimizing downtime.

The construction and design of the system reflect both durability and aesthetic quality. The structure is made from high-grade corrosion-resistant materials to ensure reliability and long-term use in medical environments. Despite its compact footprint (54×56×148 cm), the system provides easy access for maintenance, filter replacement, and inspection. The sleek, modern design ensures that it fits seamlessly into medical laboratories and cleaning rooms without occupying excessive space.

From a safety and compliance perspective, this model is fully aligned with medical water standards and infection control protocols. The system ensures that every drop of produced water is free from microbial contamination and suitable for use in endoscope reprocessing, dental cleaning, and medical instrument disinfection. The microbial limit is maintained at ≤10 CFU/100ml, protecting patients and equipment from potential cross-contamination risks.

In addition to performance, the system emphasizes energy efficiency and low operational cost. With a rated power of only 0.6kW and optimized water recovery rate, it delivers excellent output-to-energy ratios. Its intelligent washing and flushing cycles extend the lifespan of the RO membrane and filtration components, reducing long-term maintenance costs.

The 120L/H Medical Pure Water System represents a comprehensive solution for healthcare facilities that demand uncompromised water purity, reliability, and compliance. Whether installed in a central sterilization supply department (CSSD), endoscopy center, or dental clinic, this equipment delivers stable performance, consistent water quality, and intelligent control features that support safe and efficient medical operations.

Key Benefits Summary:

Consistent water quality meeting WS 507-2016 standards

Comprehensive multi-stage sterilization process

Real-time conductivity and performance monitoring

Compact, robust, and user-friendly design

IoT-enabled intelligent management

Low maintenance, energy-efficient operation

With its advanced purification technology, robust build, and smart automation, the Medical Pure Water System provides a dependable foundation for safe and efficient medical cleaning workflows — ensuring both patient safety and operational excellence.

EQUIPMENT WORK FLOW CHART

EQUIPMENT PARAMETER INFORMATION

| EQUIPMENT PARAMETERS AND RELEVANT REQUIREMENTS |

| Equipment model | YS-RO-120L/H | Water quality standards | WS 507-2016 |

| Water output | 120L/H |

|

| Quality of water production |

| Microbial limit | ≤10 CFU/100ml |

| Electrical conductivity μs/cm(25°℃) | 0.005 |

| Additional information |

| Equipment size | 54*56*148cm |

| Usage requirement |

| Incoming water pressure | ≥0.3MPa |

| Influent quality (TDS) | ≤150ppm |

| Power supply | AC220V±10% 50HZ |

| Rated power | 0.6kw |

| Scope of application |

| Endoscope room disinfection and cleaning water |

EQUIPMENT CHARACTERISTICS AND ADVANTAGES

| Features | Advantages |

| Beautiful appearance | Stable water quality |

| Automatic start and stop | High water purity |

| Brand equipment accessories | Independent intellectual property rights |

| Easy installation | Internet of Things |